Because of poor design of gating system. Use this family tree to select risering method for your production conditions24.

Riser And Gating Design Engineers Knowledge

Casting simulation does not provide the initial riser design for a casting.

. In the investment casting gating system design we can categorize this according to the three facts. However it is observed that the mold preparation in most of local foundries in Palestine depends totally on the experience of the foundry man who does not pay much attention to the engineering mold-design procedure. As it is a completely theoretical try the concluded results may not match with the real time situations.

It may experience different defects such as crack porosity hot tear etc. Design and Analysis of Gating and Risering System for Casting of Ball Valves. In Casting design the gating riser system design has a direct influence on quality of cast component.

How it is filled. RISERING LIQUID CONTRACTION WITH GATING SYSTEM. Gating and Risering Basics introduces the learner to the various components of the filling and feeding systems as well as their role and design in transporting the molten metal into the casting cavity.

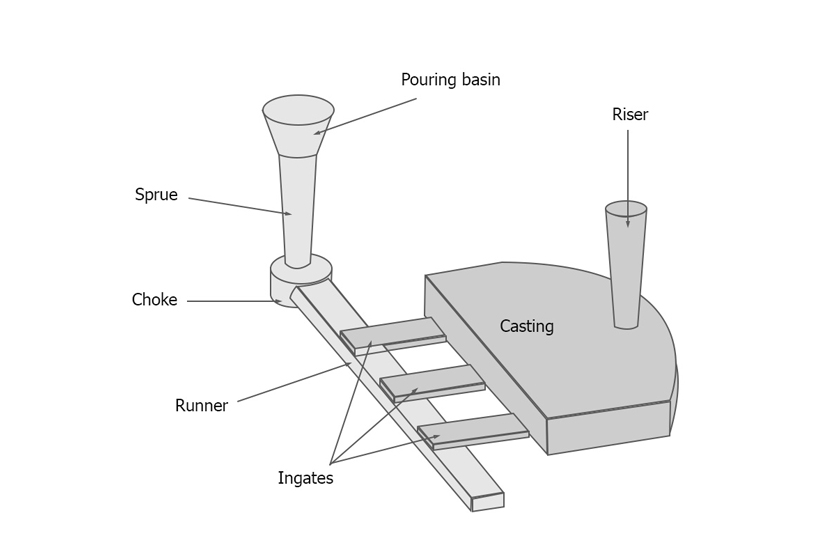

ELEMENTS OF GATING SYSTEM 1Pouring basin 4. Mainly depend on gating system. This course guides participants through the basic functions of gating and risers to provide clean sound and functional castings.

Gatingriser system design is optimized to improve casting quality. Gating system include distribution of clean metal with proper rates and velocities at specific location in the mould. PARTIAL RISERING WITH GATING SYSTEM.

In order for the PCR system to function correctly the gating system must be isolated from the casting and riser very soon after mould pouring is complete. Most engineering problems casting designs done trial and error basis. BASIC PRINCIPLES OF GATING AND RISERING PDF - Our job is to design a practical gating and risering systems for the proposed casting In General.

Riser system is designed using full considerations on the shape size and the position or location of the riser in the mold. This knowledge is foundational for designing the gating and risering systems for efficiently filling of the mold cavity to produce quality castings. Runner 2Down sprue 5.

Whether it is open to the air. The three ways that risers should be designed for cast iron are explained along with the factors that affect volume change. Software can be used in place of actual casting trials to detect feeding and risering problems in a steel casting the present rules still serve several important purposes.

Casting simulation utilizes finite element procedures depending upon the complexity of the problem. The method consist of calculating the optimum pouring time of the casting which is cross checked with minimum rate of rise of metal in the mould. But if it is located next to the casting it is known as a side riser.

20 0 05 MODULUS inch. In the thesis one engine block is used to verify the effectiveness of the optimization method. A C programme has been developed to calculate the areas of sprue runner and ingates and volume of the riser.

Penetration of liquid metal into mould walls. GATING Gating are flow passages to run and fill molten metal in mould cavity. Namely the gating and Risering systems.

Gatingriser system design is critical to improving casting quality1. As cracks hotspot mis-run etc. Gating design directly impacts casting quality and yield.

Selection based on mould strength and casting. Casting is suitable economical manufacturing process for various components. The objective of project is to design and simulate gating and risering system components by using simulation technology to get defect free casting.

Defects occurring due to improper design of gating system-Oxidation of metal. On the other hand the paper presents a useful summery of a list of the most important references related to the design of Gating and Risering systems in sand casting. Because of poor design of gating and risering system.

By the end of this module you will be able to list unique riser considerations for iron castings. An empirical way of risering is also formulated with some little success without following the results concluded by prior researchers. Gating and riser system are designed with the help of mathematical formulae.

For design purposes M G 02 M N. Gating System Gating Risering Casting Defects Gating Design The Design of Gating System Bangladesh University of May 13th 2018 - MME 345 Lecture 14 The Design of Gating System 2 Introduction to the gating system Ref 1 P Beeley Foundry Technology Butterworth Heinemann 2001. An introduction to fluid flow and solidification will serve to guide participants through key design concepts of the various functional elements of good gating and riser design.

Design the gating with limited amount of empirical results concluded by the leading researchers of 1960s. Casting as a manufacturing process to make complex shapes of metal materials in mass production may experience many different defects such as porosity shrinkage blowhole and incomplete filling. RISERING LIQUID CONTRACTION WITH RISER.

Compared with the initial design it is found that the optimized casting design can decrease porosity around. If the riser is situated on the casting it is known as a top riser. Where it is situated.

The present rules can be used to develop the first trial riser design. It provides a large range of. The success of a sand casting process depends mainly on the design of efficient mold rigging systems.

46 Design of gating system A number of methods for calculating gating systems are. Gatingriser system design is critical to improving casting quality. This can be achieved by ensuring the gate has a low modulus M G fast freezing compared to the liquid transfer modulus M N.

Availability of modern software tool give designer an insight into the detail of fluid flow heat transfer. Chapter 4 Gating System Risering. Available in technical literatures today.

This module identifies the uniqueness of feeding graphitic cast iron alloys.

Design And Analysis Of Gating And Risering System For Casting Of Ball Valves Semantic Scholar

Knowledge Of Gating System Types Of Gating System Gating Ratio Diagram

Agent Based Risering And Gating System Download Scientific Diagram

Agent Based Risering And Gating System Download Scientific Diagram

Ductile Iron The Essentials Of Gating And Risering Sorelmetal

Gating And Risering Basics Thors Elearning Solutions

Riser And Gating Design Engineers Knowledge

Previous Gating And Risering System Cad Model Of Methoding Top And Download Scientific Diagram

0 comments

Post a Comment